Commercial Grows

CUT THE DUCT

EasyRoots Reinvented HVAC for Cannabis in 2016

We realized a gap in the market: HVAC for Indoor Grows typically costs too much, takes on too many complexities, or is designed for seasonal cooling.

With multiple customers in nearly every legal state, we have supplied cost-saving HVAC systems that eliminate unnecessary construction costs and provide immediate payback through utility efficiency rebates and tax credits. Considering budget, electrical, structural and space limitations common to most indoor grow facilities, your EasyRoots system could be game changing.

EASYROOTS

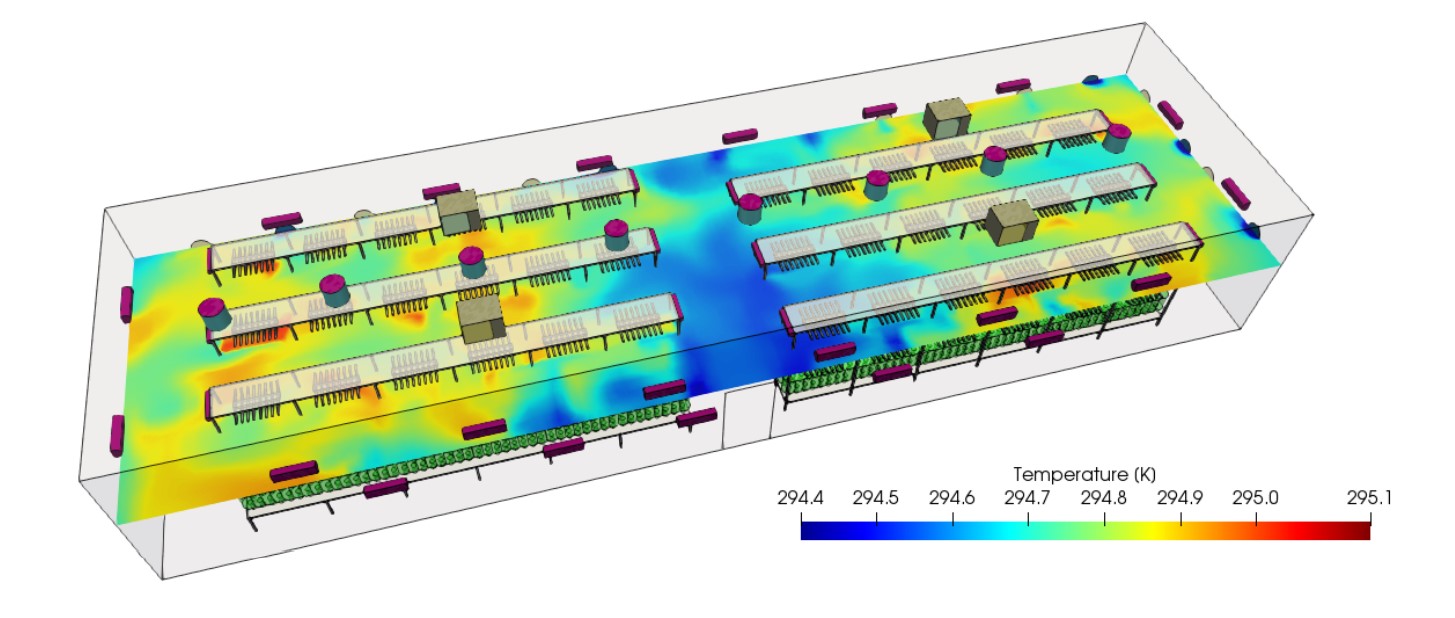

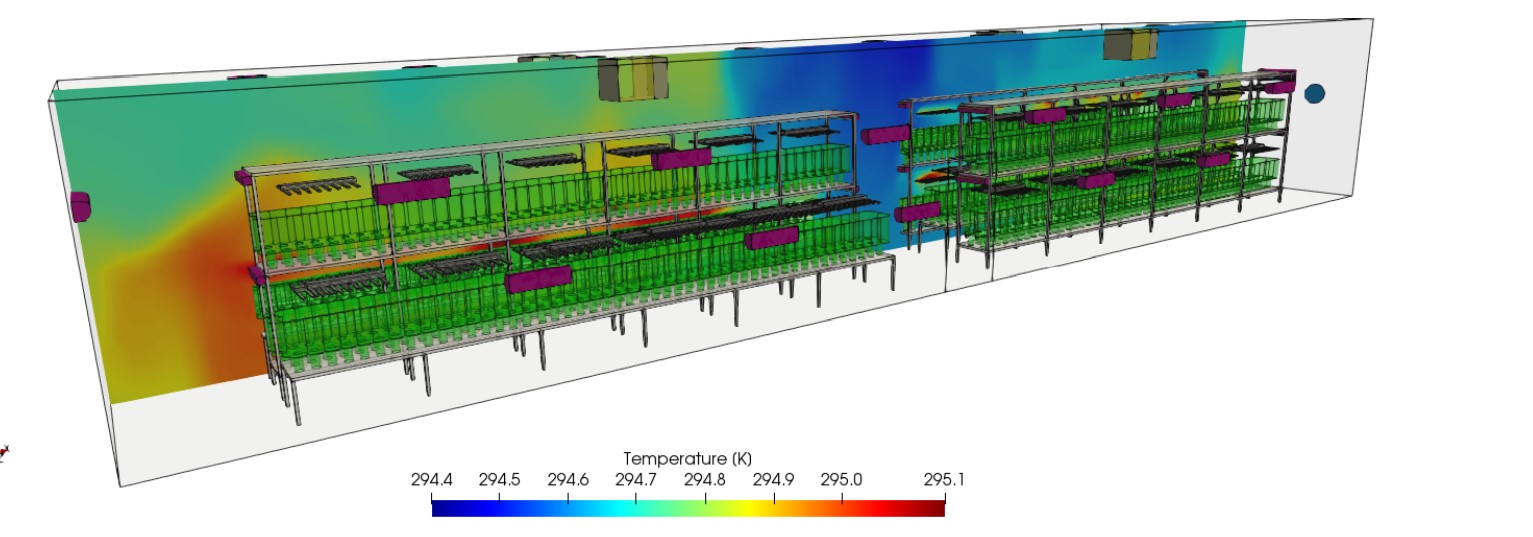

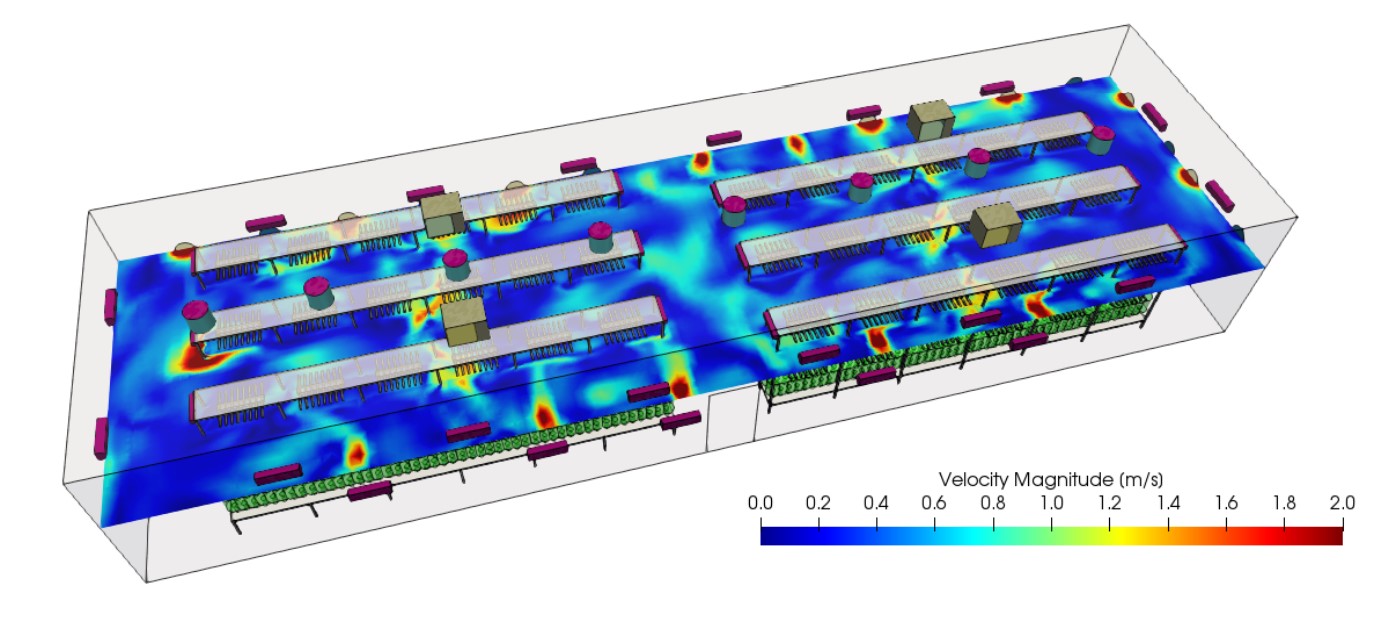

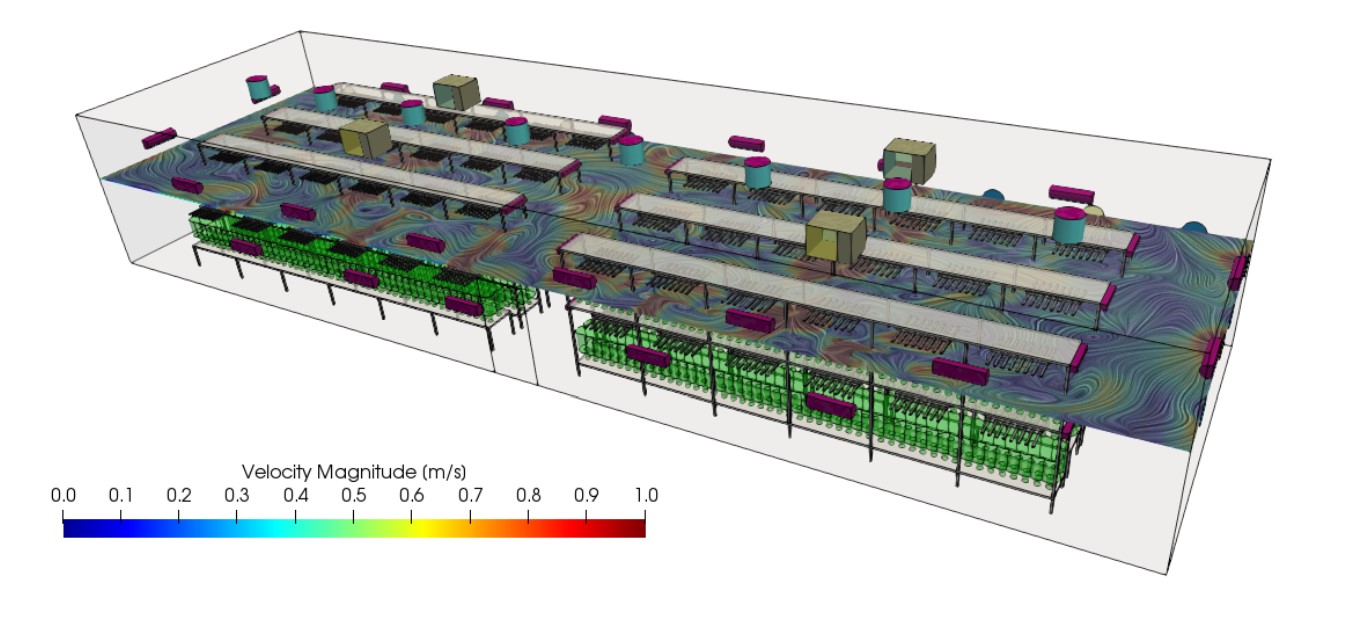

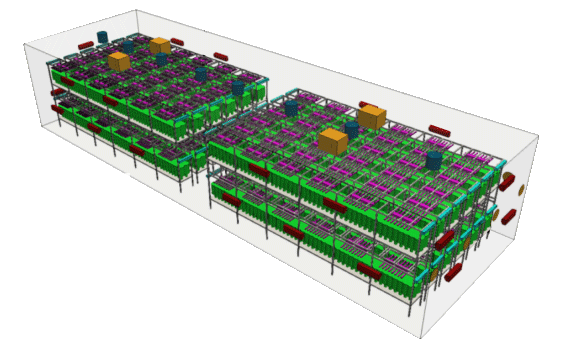

Multi-tier Grow Room Design

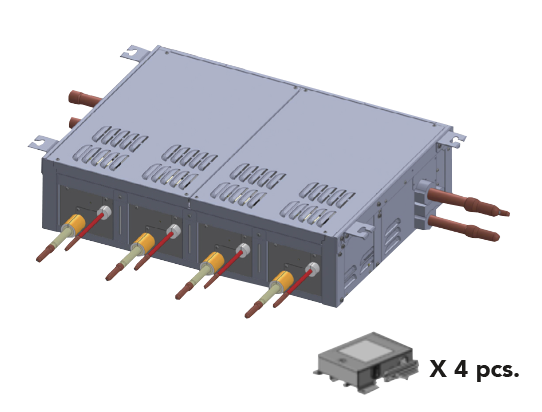

Heat Recovery Box to Recycle Waste Heat

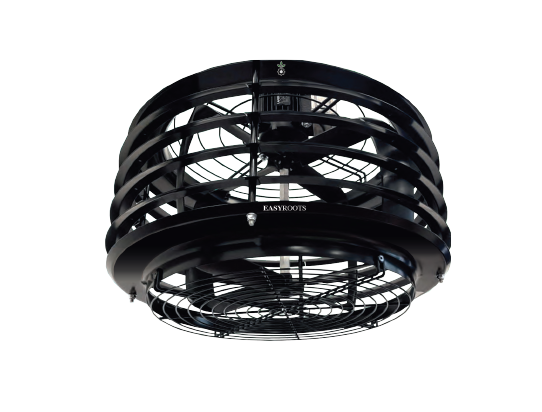

Air Mixing Fans

Compact, Ductless Air Handlers

Crossflow Fans for Lower Tier Air Movement

Outdoor Units with Severe Weather Protection

Common Misconceptions

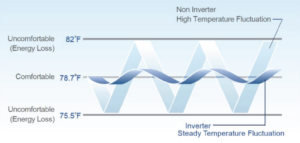

Make Your Grow More Efficient

Give us a call to schedule a risk-free consultation.

Need help with Mechanical, Electrical and Plumbing Engineering?

Put your email in and we’ll be in touch!

(We do not share your data with anybody, and only use it for its intended purpose)