In the bustling world of commercial cannabis cultivation, every detail matters. From lighting to humidity control, each aspect plays a crucial role in ensuring the health and vitality of the plants. Among these considerations, the management of carbon dioxide (CO2) levels stands out as a fundamental factor that directly impacts the growth and yield of cannabis crops. This is where a well-designed CO2 exhaust system steps in to play a pivotal role balancing optimal cultivation and being compliant with local mechanical building codes.

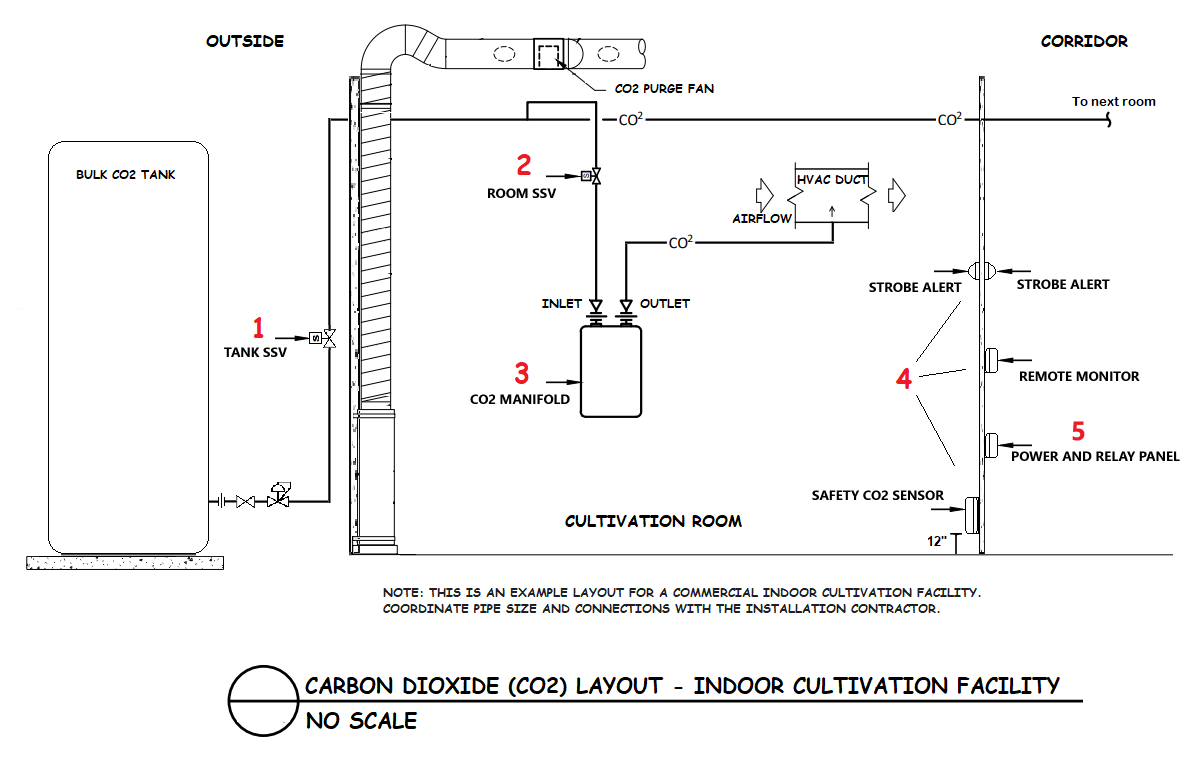

CO2, along with light and water, is one of the essential elements in photosynthesis, and is typically maintained around 1500 PPM (Parts per Million) in most cannabis grow rooms during the flowering cycle. For human health and safety, mechanical building codes will often require a means of exhausting CO2 should levels rise to the 2500 to 3000 PPM or greater range. This creates a need for an enrichment and exhaust systems to create full control over your plants CO2 uptake.

In a commercial cannabis cultivation facility, where large numbers of plants are grown in confined spaces, maintaining optimal CO2 levels can be challenging. Without proper ventilation and circulation systems, CO2 can accumulate to levels that exceed what plants can effectively utilize. This can lead to a phenomenon known as CO2 saturation, where additional CO2 provides diminishing returns and can even become harmful to plant health. Further, CO2 is heavier than air and will often settle below plant benches where it can’t be absorbed. Vertical destratification fans can help pull CO2 upwards and outwards to scatter CO2 dense air over your plant canopy to improve uptake and resulting yields.

This is where a well-designed CO2 exhaust and air mixing system proves its worth. By efficiently removing excess CO2 from the growing environment, these systems help prevent saturation and ensure that plants have access to the optimal levels of CO2 needed for robust growth. Additionally, exhaust systems play a crucial role in regulating temperature and humidity levels, creating a comfortable and productive environment for cannabis cultivation.

But the importance of a CO2 exhaust system extends beyond simply maintaining ideal growing conditions. In many regions, commercial cannabis cultivation facilities are subject to strict regulations regarding air quality and emissions. A reliable exhaust system helps ensure compliance with these regulations by effectively managing CO2 levels and preventing the release of potentially harmful gases into the surrounding environment.

Moreover, a well-maintained CO2 exhaust system can contribute to energy efficiency and cost savings. By efficiently removing excess CO2 and regulating environmental conditions, these systems can help optimize the performance of other equipment, such as lighting and HVAC systems, reducing overall energy consumption and operational expenses.

In conclusion, the significance of a CO2 exhaust system in commercial cannabis cultivation cannot be overstated. From enhancing plant growth and yield to ensuring regulatory compliance and cost-effectiveness, these systems play a multifaceted role in the success of modern cannabis cultivation operations. By investing in quality exhaust systems and implementing sound environmental management practices, cultivators can maximize their productivity while minimizing their environmental footprint.

Make Your Grow More Efficient

Give us a call to schedule a risk-free consultation.

- 833-EASYBUD

Sign up to our Newsletter

(We do not share your data with anybody, and only use it for its intended purpose)